Rotors of turbochargers for passenger cars and commercial vehicles are balanced by methods that enable an economical and reliable production of these high-speed units.

The measurement of the unbalance of turbocharger components such as compressor wheel or wheel and shaft assemblies, takes place in an air bearing at “low” speeds with high precision. The rotors are accelerated to measuring speed in Hofmann’s component balancing machines using a precisely controlled compressed-air drive and then decelerated again. The unbalance correction then occurs in two planes by milling or grinding.

Prebalancing the components ensures the complete turbocharger core assembly only has a limited unbalance allowing for a safe acceleration of the rotor to maximum speed during the measurement of the CHRA.

During the unbalance measurement of the CHRA, the core assembly is accelerated to speed via a closed loop air drive system. During this ramp up, the part’s vibration is recorded and unbalance is determined for either a one or two plane solution.

The High Speed Balancer is designed to minimize axial loading of the rotating assembly by equalizing pressures on both compressor and turbine wheels, thus eliminating scoring of the thrust bearings.

For larger turbochargers, e.g. in commercial vehicles, it may be sufficient to measure the unbalance only at low speeds.

Type 24-HSCB

The Hofmann Model 24-HSCB machine offers OE class High Speed Core Balancing of passenger car and light commercial vehicle turbocharger CHRAs (Centre Housing Rotating Assemblies).

Special features

Application

![[Translate to Englisch:] Typ 24-HSCB für das hochtourige Auswuchten von Turboladerrumpfgruppen](https://www.hofmann-global.com/fileadmin/user_upload/Produkte/Spezialloesungen/Automotive/hofmann_pure_power_hscb.jpg)

Types 24- and 60-LSCB

Hofmann model 24-LSCB and 60-LSCB offer OE class Low Speed Core Balancing of standard and heavy-duty commercial vehicle and marine turbocharger CHRAs (Centre Housing Rotating Assemblies).

Special features

Application

![[Translate to Englisch:] Maschinen zum niedrigtourigen Auswuchten von Turboladerrumpfgruppen](https://www.hofmann-global.com/fileadmin/user_upload/Produkte/Spezialloesungen/Automotive/hofmann_LSCB.jpg)

Type R-13-SW

The Hofmann Model R-13-SW machine offers balancing of wheel and shaft assemblies from turbochargers for passenger cars and commercial vehicles.

Special features

Application

![[Translate to Englisch:] Baugruppe zum Auswuchten von "Turbinenrad und Welle"](https://www.hofmann-global.com/fileadmin/user_upload/Produkte/Spezialloesungen/Automotive/hofmann_r13sw.jpg)

Type R-13-CW

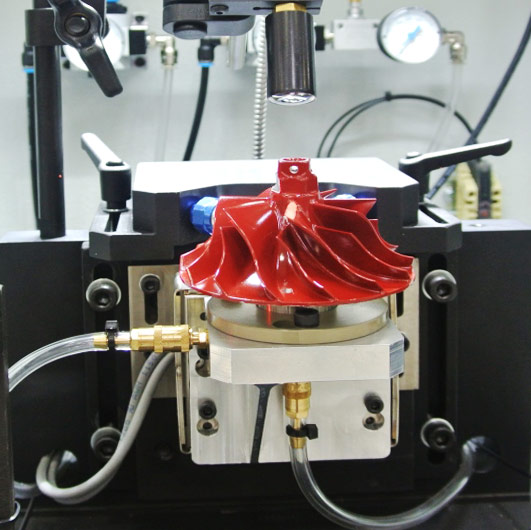

The Hofmann Model R-13-CW machine offers balancing of compressor wheels for turbochargers used in passenger cars and commercial vehicles.

Special features

Application