Engines for the aviation industry have the highest requirements concerning reliability. Hofmann balancing machines and balancing devices meet these requirements to reliably balance rotors from aircraft engines and their components.

Rotors from aircraft engines undergo precisely defined procedures with multiple steps during manufacturing and overhaul in order to achieve minimum vibrations and high efficiency. So even though the rotors are flexible, they can be balanced at low speeds using the methods of rigid rotor balancing.

In order to balance engine modules and assemblies Hofmann offers a complete line of horizontal hard-bearing balancing machines. All machines in this series meet the latest SAE-standards.

Disks – with or without blading - or spacer rings are balanced on vertical hard-bearing balancing machines in one or two correction planes.

For engine manufacturing Hofmann offers special balancing cells, in which a balancing machine is linked to a machine tool for controlled correction of the unbalance, for example by milling. This makes the overall balancing process even more precise and efficient.

Hofmann moment weighing scales are used to measure the unbalance effect of blades in one or three axes. The measured values are evaluated by Hofmann’s BLADES software, in order to distribute the blades in a way that reduces overall residual unbalance.

Finally, Hofmann offers tooling in order to precisely support and adapt components, modules and assemblies for the balancing process.

The solutions for balancing of rotors from aircraft are also available for rotors from stationary turbines.

Types H-12J to H-26J

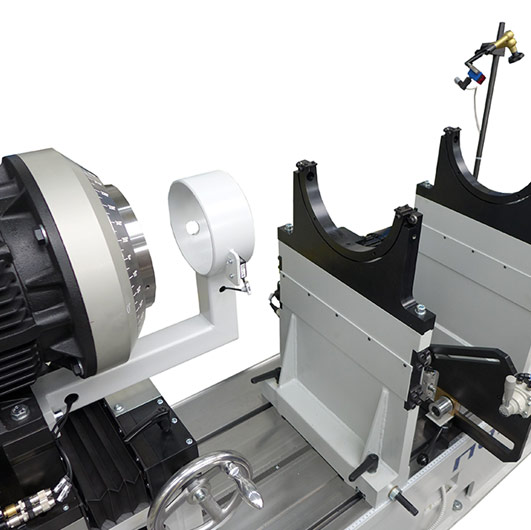

The horizontal hard-bearing balancing machines for the aviation industry are used for precision balancing of engine components. The machines are designed to meet SAE ARP 4048 standard, and can be customized with a variety of options. They are well prepared to meet the current and future requirements of the aviation industry.

Expansion options such as half-shell bearings or special software make it possible to balance all standard rotors in the aviation industry. For example, averaging the results of multiple balancing runs reduces the influence of movable blades on the measuring result.

Custom designed safety measures keep the machines safe and reduce the noise emission with integrated sound insulation.

Special features

Application

Types V-10J to V-400J

The vertical hard-bearing balancing machines for the aviation industry are used for the precision balancing of engine components that do not have their own journals. These rotors are clamped on a vertical precision spindle by means of special tooling. Because these machines are designed to meet SAE ARP 4050 and 5323 standards and have a variety of options available, they are well prepared to meet the current and future requirements of the aviation industry.

Rotors in the aviation industry can be easily balanced thanks due to the availability of options like automatic measuring mode or special software solutions. For example, by averaging the results of multiple balancing runs the influence of movable blades on the measuring result is reduced.

Flexible concepts for safety enclosures reduce the risk of danger and provide ergonomic access to spindle and rotor tooling.

Special features

Application

Types HWS-1 to HWS-240

The Hofmann moment weighing scales for the aviation industry are used to precisely determine the center of gravity of engine blades in one or three axes. Designed to meet SAE ARP standard and available with a variety of options, these machines are well suited to meet the current and future requirements of the aviation industry. This process can be implemented in power generation turbines, as well.

The moment weighing scales use the force measuring method. Therefore, they are permanently calibrated and are not affected by temperature fluctuations. Due to the special frictionless support and secure fit of the measuring arms, there is no wear and the scales maintain high precision regardless of the weight of the part.

The optional BLADES software package assists in the sorting of a blade set and ensures an optimal distribution of unbalance.

Special features

Application

Types R-50.1HS and R-150.1HS

The Hofmann balancing machines R-50.1HS und R-150.1HS are used to balance drive shafts from aviation engines or aviation drive systems at high speeds. These drive shafts generally show flexible behavior, so they should be balanced at operating speed and checked for runout.

Special features

Application

The innovative Hofmann balancing cells connect one or more balancing machines with a machine tool. The unbalance evaluated by the balancing machine will be automatically corrected on the machine tool. The measuring system transfers the unbalance data to the control of the machine tool. As a result, parts with complicated geometry or special materials can be precisely corrected with reduced operator influence.

Special features

Application

![[Translate to Englisch:] Hofmann Auswuchtzellen für die Luftfahrtindustrie](https://www.hofmann-global.com/fileadmin/user_upload/Produkte/Spezialloesungen/Luftfahrt/hofmann_auswuchtzellen.jpg)