In addition to special balancing solutions, we also offer state-of-the-art rotor spin solutions. In high speed ranges, subsequent shifting or setting likely causes a change in the rotor unbalance.

For ideal balancing results before series production, it is therefore essential to spin the components in the operating speed range.

Tel.: +49.6157.949.0

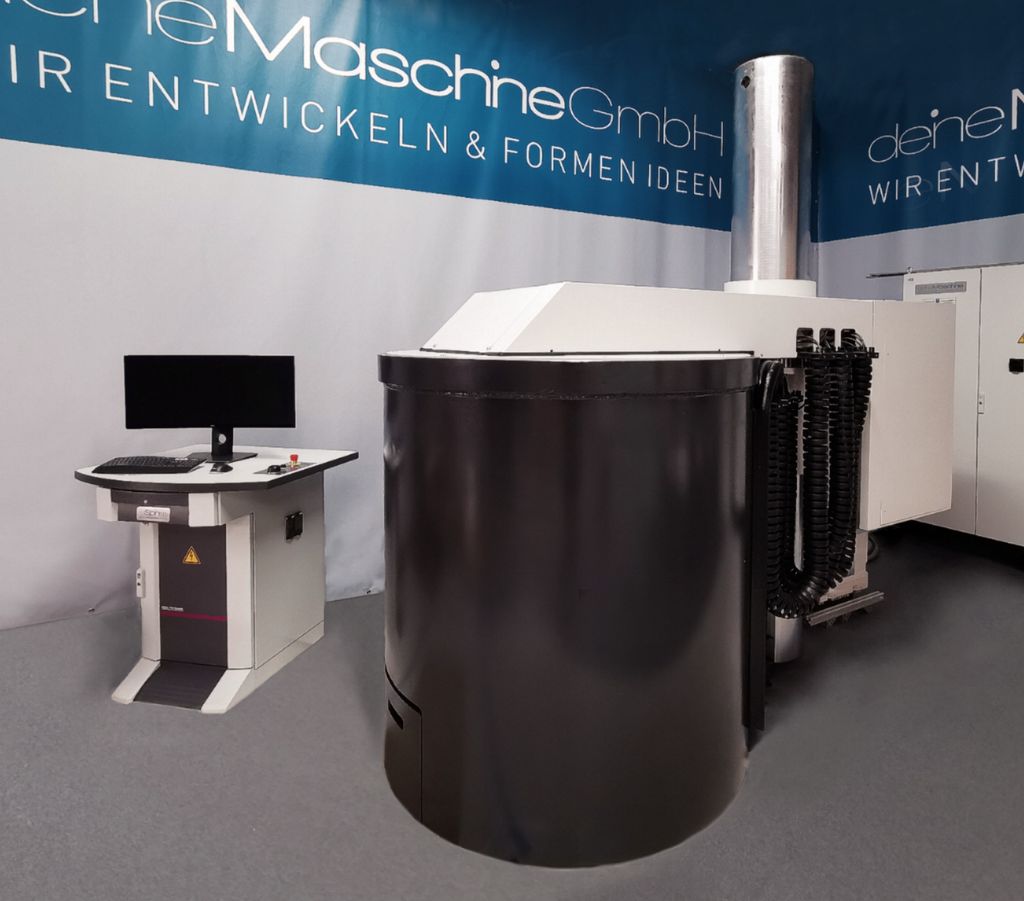

Spin bench for e-mobility rotors

The balancing of electric rotors also includes accelerating them to their later operating speed in the vehicle. This run-up to operating speed - also known as spinning - often leads to a shift in the mass of the laminated cores within the rotor, which in turn leads to a changed unbalance.

With regard to the relatively low unbalance tolerances of the E-rotors, a centrifugal process is essential, so that this is part of the balancing of the rotors.

The Hofmann spin benches are available in a horizontal and vertical orientation.

Loading can be done manually or automatically by a robot.

Special Features

Applications

In research and development or production in small batches, requires a detailed rotor analysis in both its resiliance and the vibrational behavior. To test limits and possibilities of your products, effective spinning solutions withstand a high-speed range and rotor weight.

For these and other applications, our partner company deineMaschine offers a wide range of solutions.

For the development, prototype testing, quality assurance and rotor production

Spin benches are indispensable for the development, prototype testing, quality assurance and production of rotors to be investigated.

Special features

Application